Flexible connectors. Wiring. Butterfly valves. All of these connections have the propensity to influence a scale. Anywhere there's a force that's applied to a scale, it's going to change the readout in weight to some degree.In certain applications, scale accuracy becomes absolutely critical. Each time you make a connection to a scale hopper, it adds a degree of inaccuracy. Every time you make a connection to a scale (whether it's a piece of wiring, a piece of seal-tight the wiring is going through or a compressed air hose) the scale can be affected.

In this post, we’ll explain how our COMPONENTER® systems are designed to minimize the tension that creates deviation in the scale weight. When dealing with micro and minor ingredients, this design can absolutely translate into consistency and quality in an end product.

A COMPONENTER® is designed so that utilities’ influences are minimized

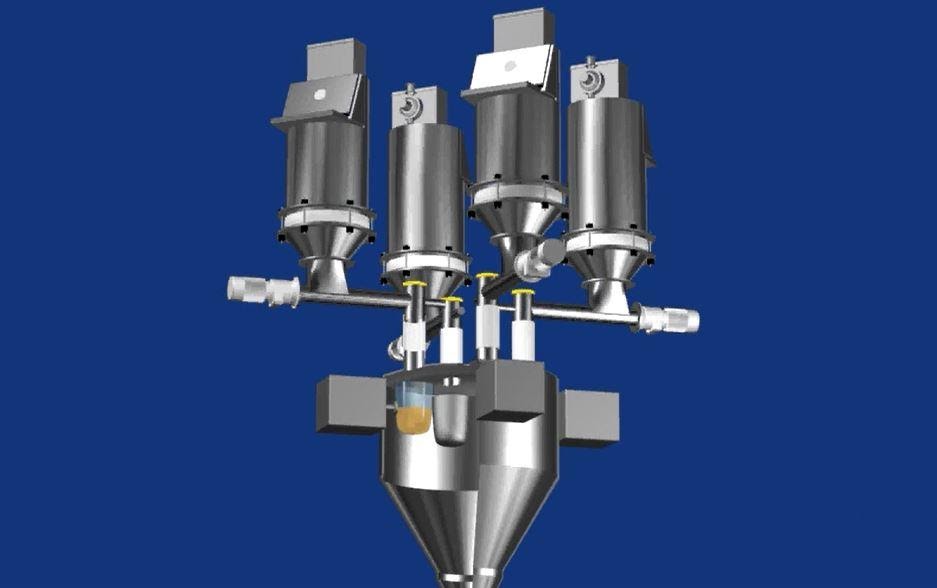

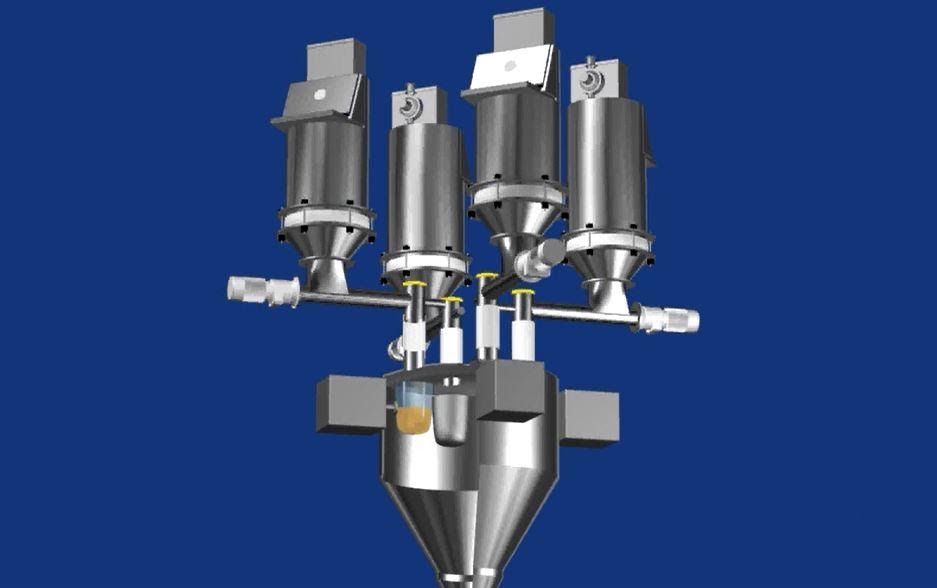

The bucket scale of an AZO COMPONENTER® is a free-floating bucket that is turned upside down during operation. This bucket is paired with the machine’s load cell in such a way that the ingredients are weighed in the most appropriately-sized container. When a unit is designed for a particular ingredient volume and weight in mind, the bucket and screw feeder are both selected so that the ingredient weighments are as accurate as possible.

In addition, all the connections that would greatly influence the scale are contained in a way that prevents stress and influence on the load cell. Grommets prevent pulling from the outside of the cover that encloses load cells and utilities. Valves, electrical wiring and seal-tight could otherwise affect the weight readout to larger degrees than they do with a COMPONENTER®. Compressed air fittings would also influence the bucket scale, but the contents beneath this cover are designed to circumnavigate this.

When weighing thousands of pounds and operating bulk scales with large weigh hoppers, the connections and utilities (that add tenths of a pound to a final reading) may not be of critical concern to a readout. They might even be a drop in the bucket by comparison. Still, exerting pressure on a weighing device when making micro-weighments inherently alters these weighments to the point of noticeable inaccuracy.

A circular COMPONENTER with a bucket scale (located inside the hopper). Wiring (located inside the box to the left of the hopper) is organized so as not to affect the bucket scale that is weighing material.

Consistency and product quality is a result of intelligent design

Consistent product measurements give you a quality result in the end. We’ve mentioned before that automated batching or mixer-feeding or ingredient-feeding systems reduce and, in some cases, outright eliminate the tedious manual weighing that is often synonymous with product inconsistencies. As soon as you start handling minor and micro additives manually, sooner or later you're going to introduce manual errors.

Still, when you are making a formula on a production-size scale with many components that have to be portioned together in accordance with the formula to make a repeatable recipe batch to batch (day in and day out), you have to have an effective system of dosing and weighing to pull it all off.

Having utilities and connections (that would otherwise interfere with weighments) designed and arranged with accuracy in mind gives you that much more of an advantage when incorporating minor and major additives into your process. If you want the same amount, every time — batch after batch after batch — a system like an AZO COMPONENTER® keeps these influences contained in a way to ensure high-quality consistent products. The fewer influences that affect scale accuracy means more accurate processes altogether.

If you’d like to hear more about our COMPONENTER® systems, feel free to download the free e-Guide available on our site. You can also contact our team of sales engineers for any other queries on automating ingredients or conveying materials. AZO has decades of experience in the ingredient automation world and tons of topics we’ve covered on our blog.