Bulk bag unloader safety features are extremely important. You need things like a full safety plate and retaining clips to protect your employees from falling bulk bags. We're engineers at heart, and most of our conversations are with engineers. So we tend to focus on direct machine details.

Those are critically important, but not the only safety considerations to weigh in the process of specifying the right processing equipment for your facility. Even a component as seemingly simple (certainly in comparison to pneumatic conveying system, batching and weighing) as a bulk bag unloader often can include components and capabilities with a big impact.

Managing dust, for example, often requires thoughtful design and has significant potential implications for facility safety, maintenance operations and worker safety.

Proactive dust management can be built into a bulk bag unloader system in five common ways:

-

Active dust control when connecting the bag spout

-

Active dust control when changing bags

-

Bag collapse capability

-

Tight, repeatable, operator-friendly connection

-

Outlet spout control

Let's dig a bit deeper into each.

Active Dust Control When Connecting a Bag Spout

This brief animation will put the next section in context.

The initial connection, controlling the spout when untying the bag, and managing the displacement of air that occurs when unloading a new bag are the first important dust control steps.

As this animation shows a bulk bag unloader should incorporate the capability to connect the spout securely and air tight. There should be easy operator access to untie the bag (it's generally easier for operators if this doesn't involve working in a small dark box). The connection should be secure so that it doesn't pull loose later (e.g., when stretching the bag to aid in complete bulk bag discharge).

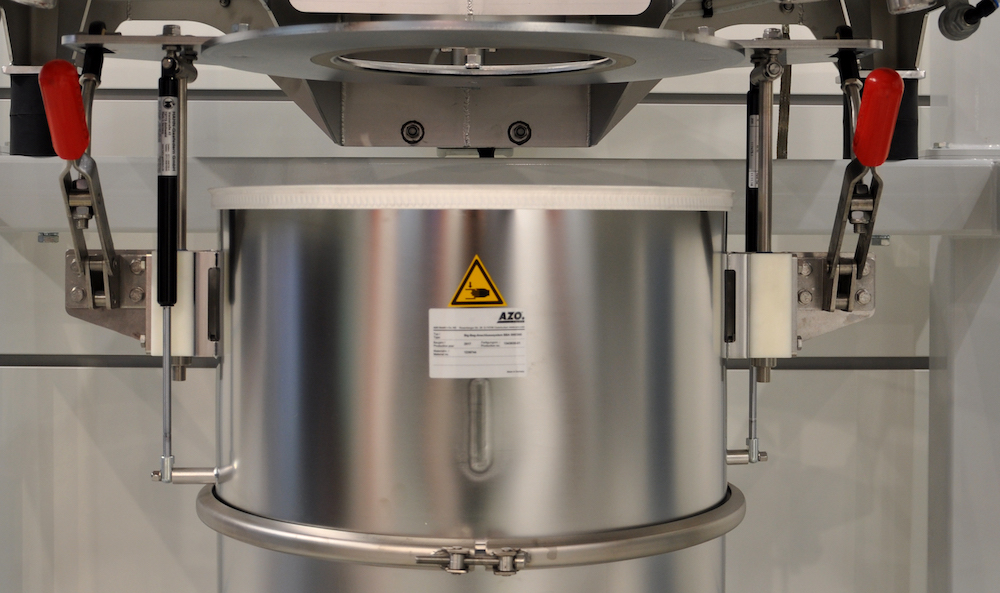

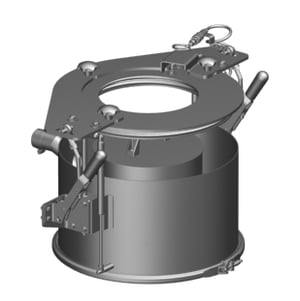

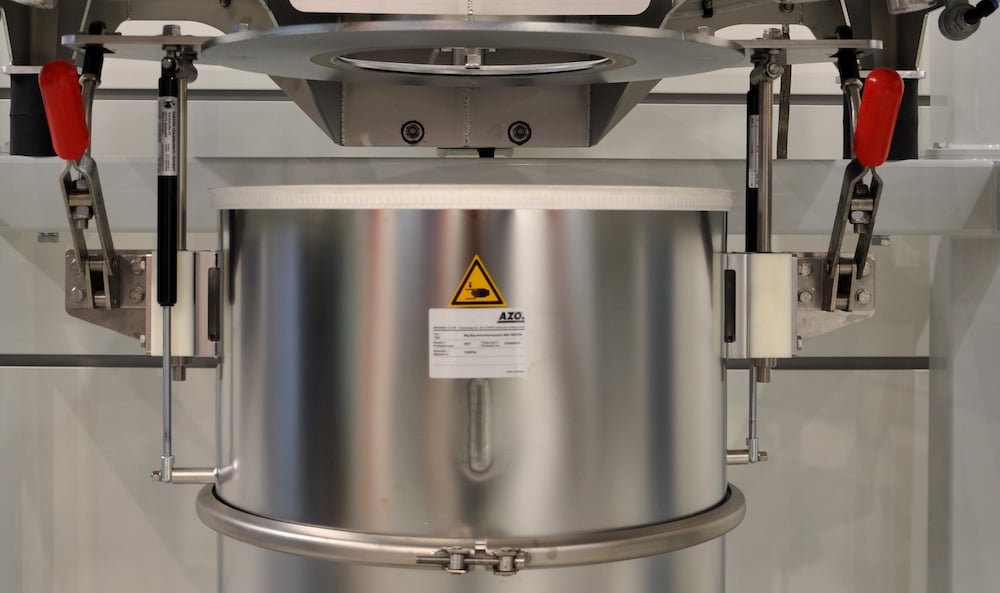

The connection unit (AZO calls it a BBA or Big Bag Adapter - see more detail here) should incorporate a cover so that the system can be sealed as soon as a bag is disconnected to ensure product integrity and prevent contamination.

As material flows from the bag, it displaces air that has accumulated. That rush of air will contain dust and must be actively controlled and vented so that the dust isn't released to become an ambient health or explosion risk or impede the flow of product below.

Active Dust Control When Changing Bags

Changing bags is naturally similar to connecting a bag, but also includes the necessity to actively control the dust that inevitably remains in the bag and circulating when the bag is disconnected. That air/dust should be actively vented as it is during the connection.

Additionally there should be a cover which locks down, sealing the system to prevent dust egress into the facility while there is no bag connected.

Bag Collapse Capability

Discarding empty bags is one of the most common sources of ambient dust. Even the most fastidious operators cannot completely discharge the contents of a bag 100 percent. Empty bags are removed from the unloader, then often manually folded to reduce the waste removal space required.

As they are folded and collapsed, most of the remaining product and dust is expelled into the work area. Operators who have been trained to minimize the waste will continue to collapse bags even when if means they're creating more dust.

A technical solution exists in the form of vacuum bag collapse. With the air-tight connection sealing the bag, a vacuum is drawn to collapse the bag, and positively control the extra air as it's removed (along with the dust and product it carries).

This process can add several minutes to the change, so intermediate storage hopper capacity needs to be considered in conjunction with the rate of flow to ensure that the dust control measure doesn't impinge on the required throughput but can more than make up for that time in maintenance activities cleaning a dusty work area.

Tight, Repeatable, Operator-Friendly Connection

You've likely spent time and money on refining your manufacturing steps to ensure consistent quality, cost and output. So it's natural to expect that your bulk bag unloader would deliver the same. Because consistent, air-tight connections are critical to dust control, an important corollary is that the connection should be easy and repeatable.

Some connection solutions may be air tight with a certain spout, or certain operator, or certain shift conditions, but it's a connection which relies on a person to make it in a particular way. Said differently, there's nothing about the connection process which ensures it's done the same every time by every person.

That's a variability which not only results in spills, leaks and possible product contamination, but it also results in dust discharge in situations where it's not air tight.

Outlet Spout Control

The bulk bag liner can play a larger role than many assume. Variability in spouts is a common complaint among operators of bulk bag unloaders. If the spout is simply too short, there's no good fix. However, it's usually a marginal issue. It's not optimal, but it will work. And the bag is connected and unloading begins.

The problem comes later as the bag is stretched to improve flow. If the connection was a manual process that isn't repeatable and easily accessed, it might not be as tight as necessary, and as the bag is stretched it can pull free, resulting in wasted product, clean-up time and of course, discharged dust.

Therefore having the strongest possible clamp on the spout is important for dust control.

Looking Closely at One Bulk Bag Connection Solution

AZO's bag connection solution is called our BBA. It's available in a variety of custom configurations for various applications, as well as standard versions for our modular, quick delivery, bulk bag unloader.

AZO's bag connection solution is called our BBA. It's available in a variety of custom configurations for various applications, as well as standard versions for our modular, quick delivery, bulk bag unloader.

Not only does it provide positive control venting, a locking cover and a repeatable consistent operator- friendly process with easy access, but its ease of use means that there are fewer complications (like time consuming and costly spills).

It makes operators' daily lives easier!

Dust Control is Important for Health and Safety

Bulk material handling involves lots of science and some art as well. It's one thing to move and mix product — it's another to do it reliably, for years, and to anticipate common and unusual complications.

Dust control is one of those. While improved safety practices make the devastating mill explosions of years past less common today, even small amounts of ambient dust can lead to respiratory problems for workers (particularly allergens), create extra and wasteful effort for janitorial/maintenance teams, and increase explosion risks.

With some proactive planning, most operations can eliminate these common, often overlooked points in the bulk bag unloading process that are the most common sources for fugitive dust. You can find the best fit for your needs with our "Bulk Bag Unloading System" guide.